Oy Lai-Mu Ab

Oy Lai-Mu Ab is a Rauma-based solid family business. Exports account for more than half of the company’s sales, and the main market areas are the Nordic countries, Europe and Russia.

Lai-Mu’s product portfolio covers three sectors: multipurpose machines (LM Trac), implements for multipurpose machines (LM Tools) and safety cabins (LM Cabins). All of Lai-Mu’s products are designed and manufactured in Rauma on the southwest coast of Finland.

Lai-Mu and Technion have solid experience in mobile machinery

Oy Lai-Mu Ab began manufacturing safety cabins in the late 1960s and safety cabin production continues to make up a significant part of the company’s operations.

The manufacture of LM Trac multipurpose machines began in 1987, at first with just one model. Today the range includes several multipurpose machines of different sizes. In 2012, Lai-Mu expanded its business and services to the manufacture of implements and is now able to provide LM Trac multipurpose machines with versatile attachments.

Technion has been developing and manufacturing electronic control systems for various machines since 1979. The company provides turnkey solutions for the electronic control of harvesting heads and loaders and is experienced in solving customer-specific control system challenges related to mobile machinery.

From early on, the idea was to combine the core competences of both companies. While Technion would take responsibility for designing and implementing the electronic control system, Lai-Mu would be able to focus all its efforts on the chassis and hydraulic system.

After fruitful negotiations and a joint concept design phase, the actual collaboration project took off in 2014. The entire electronic control system was delivered by Technion.

Scalability and cost-effectiveness at the core of the design process

The LM Trac product family covers a large range of multipurpose machines: the smallest weighs approximately one tonne (LM Trac 286) and the largest almost six tonnes (LM Trac 687). The extensive number of available implements and varying cabin functions make the LM Trac range a flexible solution for end users, but the versatility also requires a lot from the control system. It was important to Lai-Mu that it would be able to use the same system in all LM Trac products without the need for major model-specific modifications.

Lai-Mu also wanted to provide end users with a cost-effective solution. This meant that the hydrostatic transmission needed to be controlled in a way that would minimise fuel consumption both during driving and implement use without compromising the performance of the diesel engine. In other words, the control system was required to monitor and control the hydrostatic transmission in real time. In order for this to be possible, the electronic control unit (ECU) needed high computational power and the ability to control the diesel engine.

System implementation

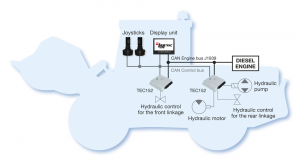

The control system was implemented using the TEC152 controller by Technion. The controller has a sufficient number of inputs and outputs for controlling the smallest LM Trac machines. In larger LM Trac machines, two TEC152 controllers were installed to perform the control functions: one for the front linkage and one for the rear linkage and the hydrostatic transmission. As the TEC152 controller had a sufficient number of CAN bus interfaces, separate bus solutions could be created for controlling the engine and the work hydraulics. TEC152 also provided sufficient computational power for complex algorithms.

One of the most important reasons for choosing the TEC152 controller for the LM Trac machines was the group of libraries and algorithms Technion had previously developed for controlling hydrostatic transmissions. They provided a flying start to the project. The existing library solutions make it easy to connect the TEC152 controller to the control bus of a diesel engine. Connecting HMI units such as graphic displays and joysticks to the controller is also simple without major investments in product development.

The structure of the new system

The diagram below shows the architecture of the control system implemented for the LM Trac 687 machine. By using two control units and two control buses, the locations of the control units could be optimised: one unit was placed near the hydraulic block of the front linkage and the other near the hydraulic block of the rear linkage. The cabin components were conveniently connected to the control system through the CAN bus.

A successful control system consists of a functional system architecture and a reliable application software. The software guarantees that machines are fuel-efficient and provide a safe work environment, an excellent driving response and an outstanding user experience. The application software used in the LM Trac machines was designed by Technion. The collaboration project was a success, and the new machines are now ready for the market.

Further information about Technion control systems and Lai-Mu LM Trac multipurpose machines:

Technion Oy

Linkkikatu 15

21100 Naantali

Toni Lomakka

Myyntipäällikkö

toni.lomakka@technion.fi

+358 50 5973376

OY LAI-MU AB

NIITTAAJANTIE 9

26820 RAUMA

TEL: +358-2-8387 2400

FAX: +358-2-8387 2444

www.laimu.fi, laimu(at)laimu.fi